Product Description

Achieve an authentic stone appearance with the convenience of resin. Warm and rich, our translucent materials are easier to work with than natural stone, opening up the possibilities.

Alabaster is a one-sided product. As a handmade engineered stone, full sheets of this material may vary in color and pattern from panel to panel, from sample to actual panel, and when back lit.

1) Quality

1-1) Specification

Alabaster is a one-sided product. As a handmade engineered stone, full sheets of this material may vary in color and pattern from panel to panel, from sample to actual panel, and when back lit.

1) Quality

1-1) Specification

| Dimension | Tolerance | |

| Length | 2400mm | ±3 |

| Width | 1200mm | ±3 |

| Thickness | 10mm | ±1 |

| Squareness | 2728mm | ±4 |

1-2) Quality Control

We are committed to be positive & aggressive in our attitude towards quality and customer service. We will not allow quality to take second place behind cost or schedule as this is our basic strategy for growth.

* Inclusions:

No more than two (2) pits, inclusions, contaminants, voids or bubbles at a maximum diameter of 1.5 mm allowed on a 1220mm X 2440mm sheet.

* All sheets are to be covered with protective masking.

* Surface:

No more than two (2) scratches, scuffs, streaks, irregularity, or texture flaws at a maximum length of 3 mm allowed on a 1220mm X 2440mm sheet. Surface damage will be evidenced by damages in protective masking.

* Top material surface is to be planed and smooth with no evidence of machine lines.

* Bottom material surface is permitted to be course with machine patterns.

* Aesthetics:

Bubbles or white spots:

Must be limited to 50mm in diameter to any single area on a sheet

Only two (2) bubble or white spot areas are permitted per sheet.

No single color within a shipped order may contain more than 10% of sheets with bubbles or white spots - even if the above specifications per sheet are maintained.

* Flatness: No more than 3 mm of bowing from the center of the panel to any exterior edge.

* Chips/Cracks: No chips or cracks on the corners or edges of the panel are tolerable.

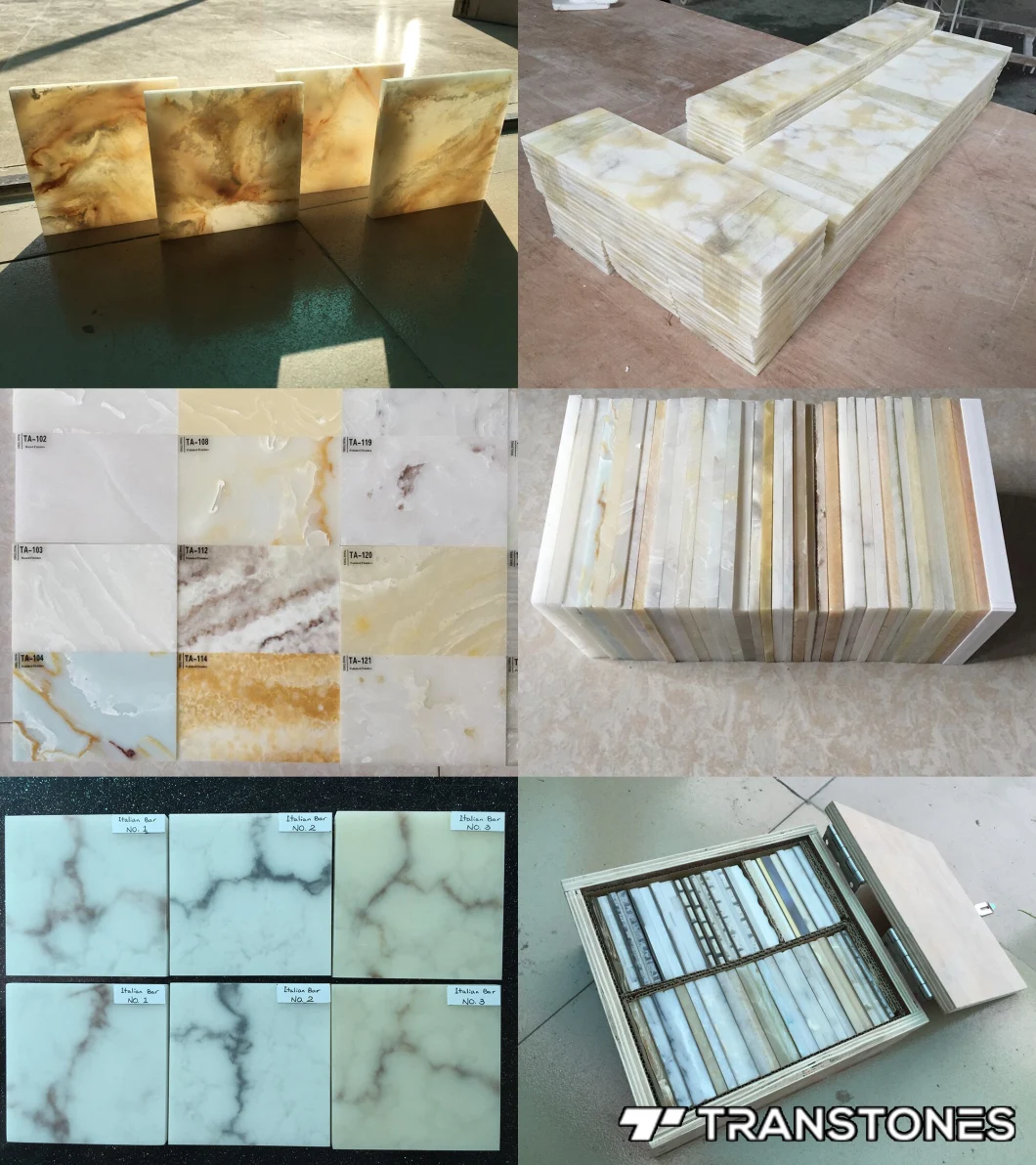

2) Colors

2-1) Colors

Our color options are available as many as you can imagine.

We are committed to be positive & aggressive in our attitude towards quality and customer service. We will not allow quality to take second place behind cost or schedule as this is our basic strategy for growth.

* Inclusions:

No more than two (2) pits, inclusions, contaminants, voids or bubbles at a maximum diameter of 1.5 mm allowed on a 1220mm X 2440mm sheet.

* All sheets are to be covered with protective masking.

* Surface:

No more than two (2) scratches, scuffs, streaks, irregularity, or texture flaws at a maximum length of 3 mm allowed on a 1220mm X 2440mm sheet. Surface damage will be evidenced by damages in protective masking.

* Top material surface is to be planed and smooth with no evidence of machine lines.

* Bottom material surface is permitted to be course with machine patterns.

* Aesthetics:

Bubbles or white spots:

Must be limited to 50mm in diameter to any single area on a sheet

Only two (2) bubble or white spot areas are permitted per sheet.

No single color within a shipped order may contain more than 10% of sheets with bubbles or white spots - even if the above specifications per sheet are maintained.

* Flatness: No more than 3 mm of bowing from the center of the panel to any exterior edge.

* Chips/Cracks: No chips or cracks on the corners or edges of the panel are tolerable.

2) Colors

2-1) Colors

Our color options are available as many as you can imagine.

2-2) Samples

2-2-1) Standard Samples

Small samples are always free for reference before ordering.

2-2-1) Standard Samples

Small samples are always free for reference before ordering.

2-2-2) Customized Samples

Any colors & patterns of Natural stone & Artificial stone are both available for us to match, feel free to let us know your ideas/designs/printed papers or send us your original samples, we will make things happen.

Any colors & patterns of Natural stone & Artificial stone are both available for us to match, feel free to let us know your ideas/designs/printed papers or send us your original samples, we will make things happen.

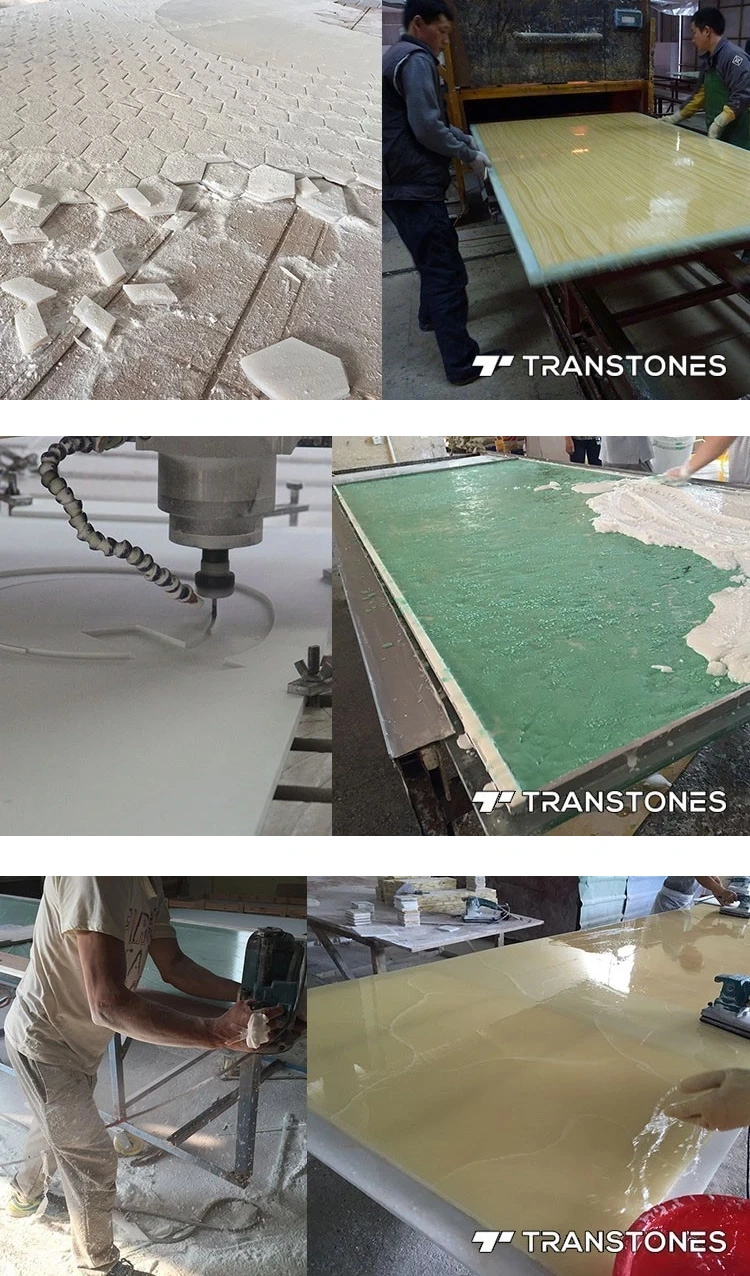

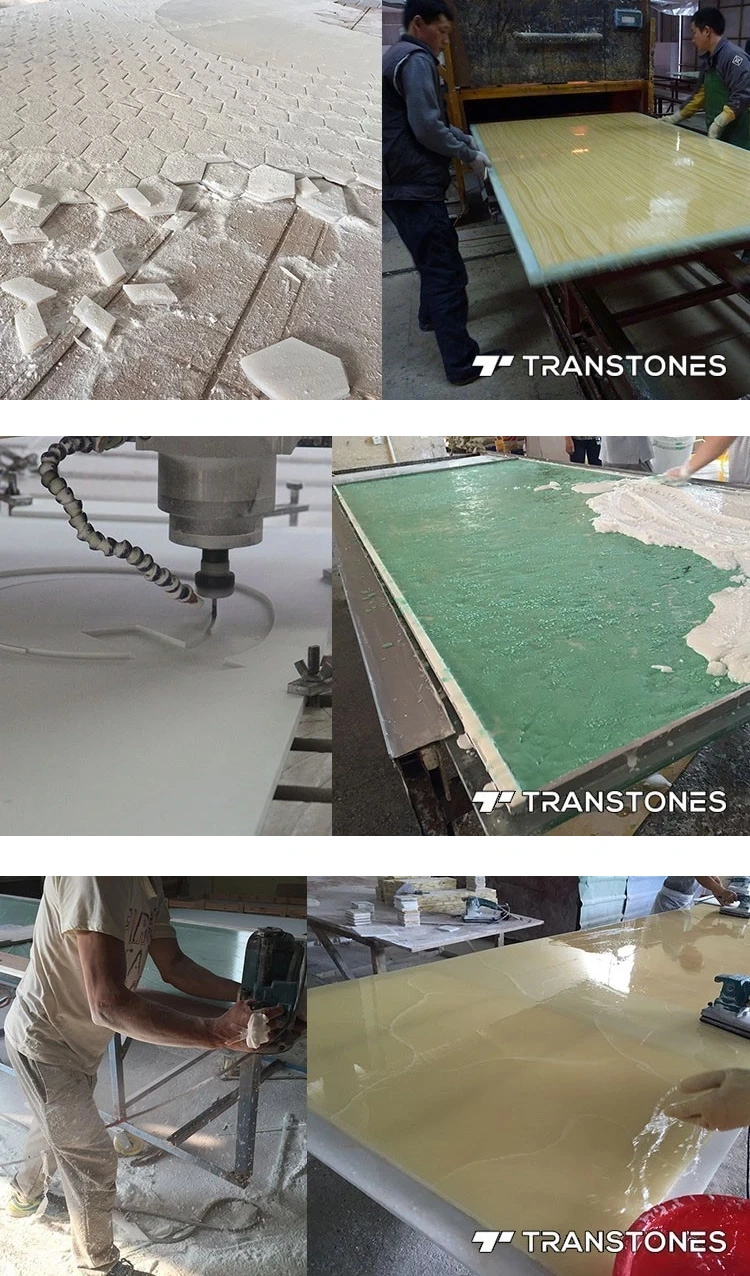

Production

Our translucent onyx slabs are offered at fair prices with an emphasis on working closely with our valued customers, we devote to supplying people with Eco-friendly and affordable office & home decor productions, leaving you a comfortable decor experiences.

Fabrication

1) Fabrication

Our resin panels may be cut with traditional wood or plastic cutting tools(band saws, circular saws or jig saws). When cutting with a panel or table saw a carbide tipped triple-chip blade is recommended. When drilling the panels, be sure to use a backing support or chipping may result. Also, drilling should be done at least 2 inches (50 mm) from any edge to prevent edge cracking.

Our resin panels may be cut with traditional wood or plastic cutting tools(band saws, circular saws or jig saws). When cutting with a panel or table saw a carbide tipped triple-chip blade is recommended. When drilling the panels, be sure to use a backing support or chipping may result. Also, drilling should be done at least 2 inches (50 mm) from any edge to prevent edge cracking.

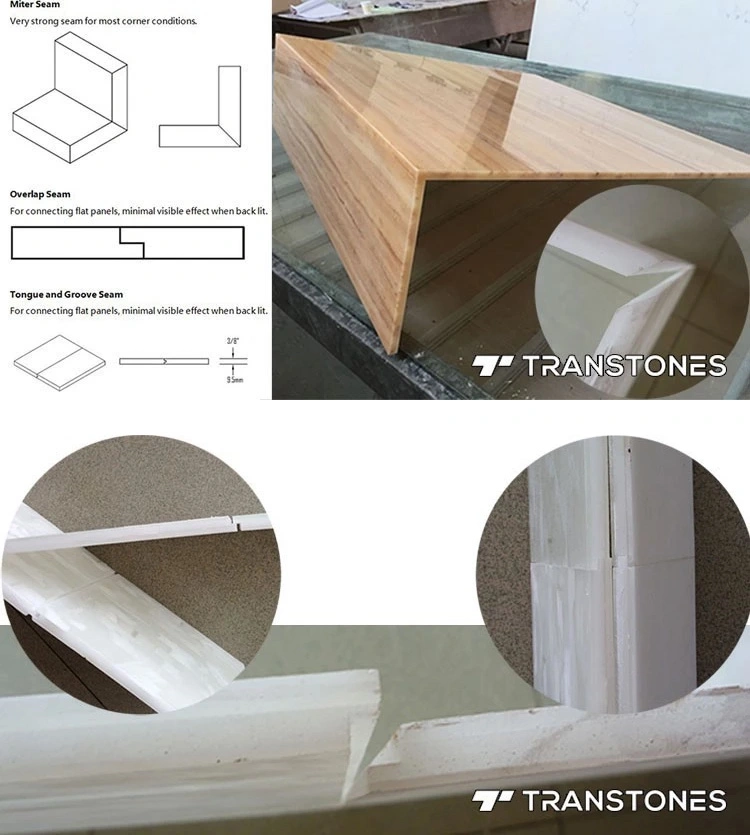

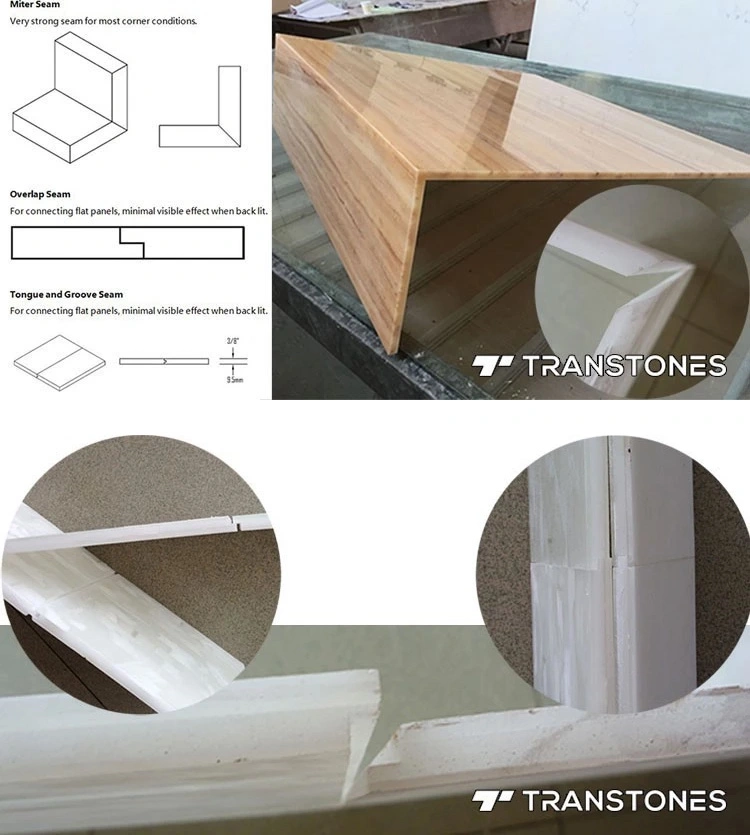

2) Jointing

There are 3 most common jointing ways for our Alabaster resin panels: Miter Seam, Overlap Seam as well as Tongue and Groove Seam.

There are 3 most common jointing ways for our Alabaster resin panels: Miter Seam, Overlap Seam as well as Tongue and Groove Seam.

Packing

Our exported cargos are always packed by specific customized fumigated wooden crates to avoid any loading & delivery damages.

Delivery

We pay close attention to every steps for loading & unloading works to ensure a smooth delivery and safe transportation.

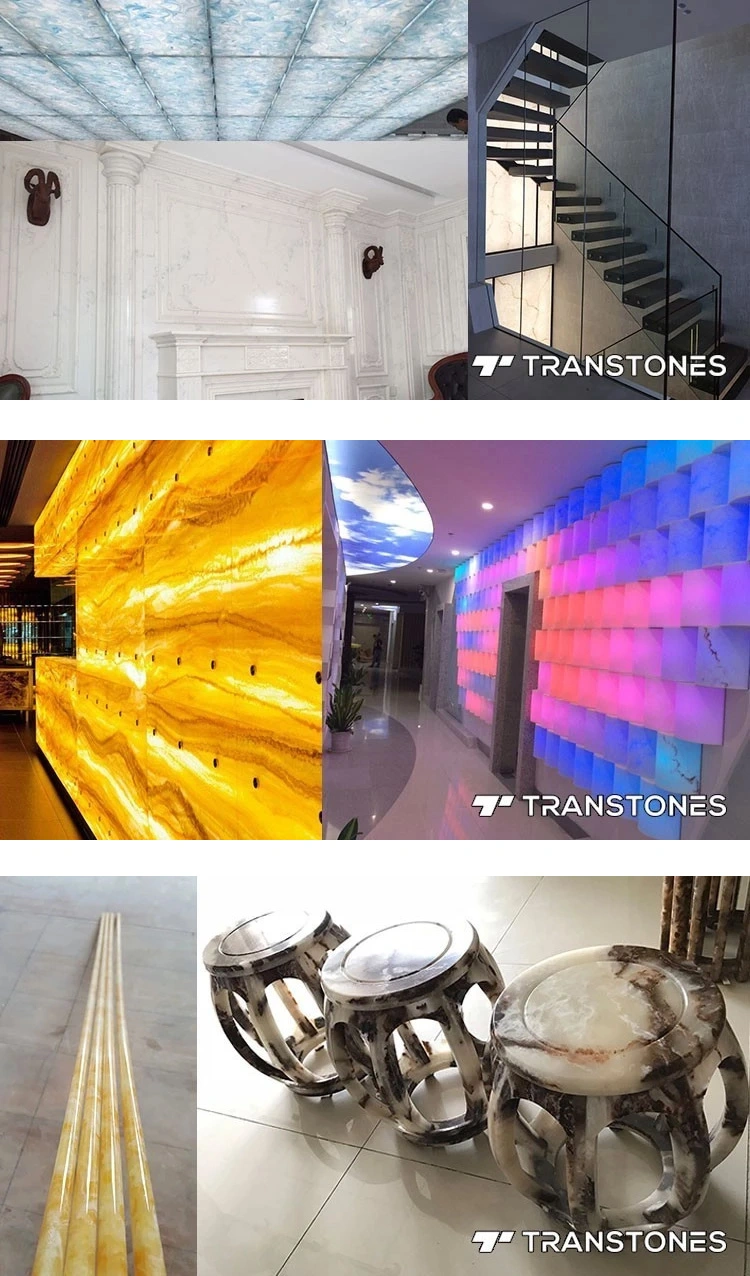

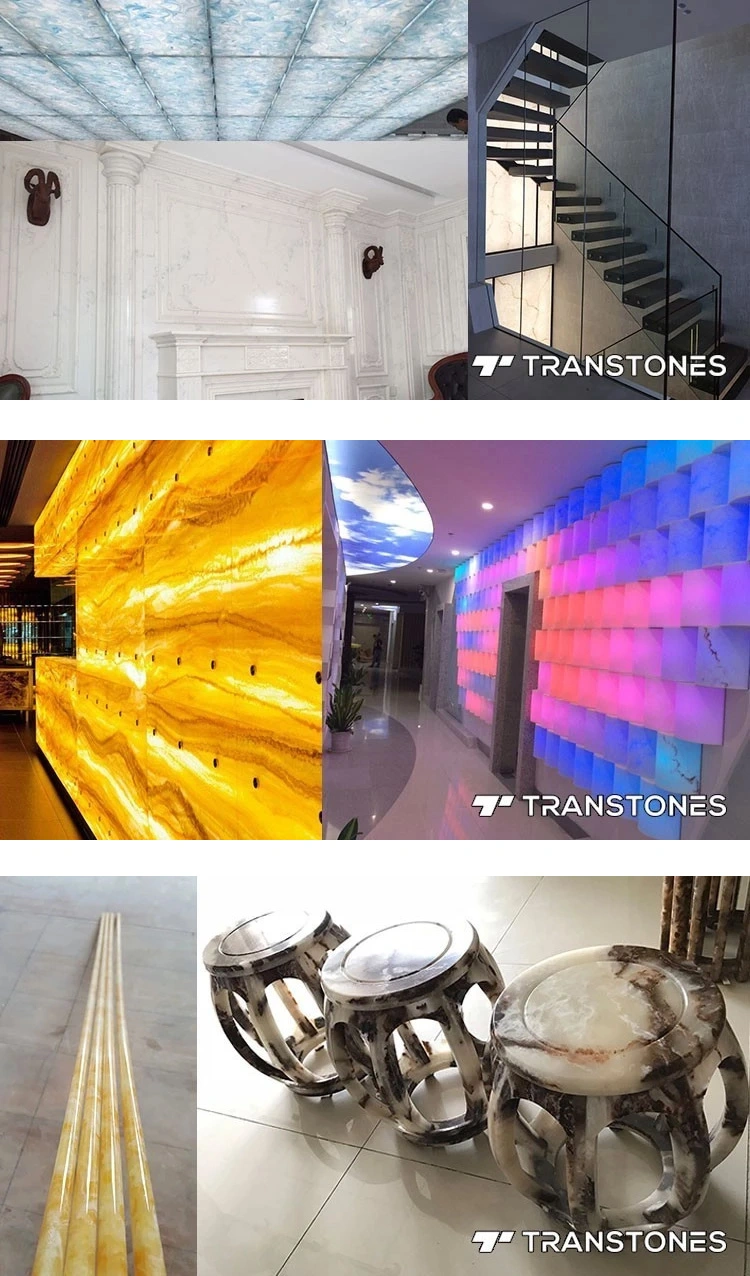

Applications

Our Alabaster resin panels are widely used for: Tables: Bar counter, reception table, tea table, dining table, etc.

Light Features

Wall and ceiling decors and others

Factory

We Transtones are committed to be positive & aggressive in our attitude towards quality and service. We will not allow quality to take second place behind cost or schedule as this is our basic strategy for growth, it has helped us grow into one of the most highly regarded suppliers of artificial stone.